In Vitro Comparison of Microhardness of Bulk Fill Flowable Composites

Kamalak H

DOI10.21767/2471-299X.1000021

Kamalak H*

Department of Restorative Dentistry, Firat University, Malatya, Turkey

- *Corresponding Author:

- Kamalak H

Faculty of Dentistry

Department of Restorative Dentistry

Firat University, Malatya, Turkey

Tel:+90-424-237-00-00(6488)

Fax: +90-424-237 89 86

E-mail: hakankamalak@hotmail.com

Received date: March 31, 2016; Accepted date: April 26, 2016; Published date: April 29, 2016

Citation: Kamalak H,In Vitro Comparison of Microhardness of Bulk Fill Flowable Composites.Med Clin Rev. 2015, 2:12. doi: 10.21767/2471-299X.1000021

Copyright: © 2016 Kamalak H. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

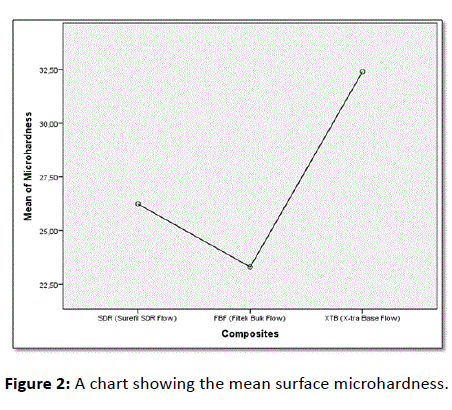

Objectives: The aim of this study was to evaluate micro hardness of three flowable bulk fill resin composites. Materials and methods: Surefil SDR Flow (SDR), Filtek Bulk Flow (FBF) and X-tra Base Flow (XBF) were used. 16 teflon molds were prepared for each group. The microhardness was measured on the top surfaces. The microhardness results were analyzed by ANOVA and Post Hoc Tukey test. Results: Microhardness values differ from 22.79-33.1. XTB were found having the highest hardness and FBF had minimum hardness value. Conclusions: Accordingly, the results of the current study indicate, it can be suggested that, XTB, SDR and XTB in clinical cases respectively. Keywords: Bulk fill flowable

Keywords

Bulk fill flowable composite; Microhardness; Mechanical properties

Introduction

Flowable composites were initially used in 1996. Flowable composite resins, developed to decrease polymerization shrinkage in adhesive applications where the cavity formation could not be established as required and to create a barrier to break stress, are commonly used in dentistry applications [1-3].

Since the flowable composites are compatible, consistent and easy to manipulate, their clinical use is quite high. New generation bulk fill flowable composite resins, with their increased filler ratios, could also be used as permanent restoration material due to their increasing physical and mechanical specifications. Producers specified that newly developed nano-particle composites could be utilized in thick layers, similarly with the traditional composites [4,5].

Bulk fill flowable composites are new kind resin-based composites has been recently introduced [6,7]. Flowable bulk fill composites (SDR, Smart Dentin Replacement, Dentsply Caulk, USA; Filtek Bulk Flow, 3M ESPE, USA; X-tra Base Flow, Voco, Germany) have love-viscosity and practical-use features. These materials have many favourable properties like as high flowability, small air bubbles, high flexibility, high viscosity and high filler content [8,9].

The characteristic of these new generation resin based bulf fill composites is placing 4 mm into the cavity [10]. Filler content of these composites are increased, so better mechanical properties especially hard materials were obtained [11].

In study performed previously, micro hardness of SDR, FBF were substantially below the mean values measured in the conventional composites especially microhybrid and nanohybrid composites In the same study micro hardness of XTB were found high. Hence, flowable bulk fill composite resins, like SDR, FBF require final capping layer, but XTB can be placed without final capping layer [9,12].

This study evaluated and compared three bulk fill flowable composites-concerning their micro hardness.

Materials and Methods

Three flowable bulk fill resin based composites were analyzed assigning micro hardness: SDR, (Smart Dentin Replacement, Dentsply Caulk, USA); Filtek Bulk Flow, (3M ESPE, USA); X-tra Base Flow (Voco, Germany). Product specifications are presented in Table 1.

4×6 mm standard teflon molds were used for bulk fill composites can be applied to the cavity at 4 mm thick and used as dentin replacement (Figure 1). After the composite material placed in the mold, it was pressed to create a flat surface and then 20 sec polymerized with LED device (Elip Freelight II, 3M-ESPE, St. Paul, MN, USA). Samples’ upper surface were made flat with polishing machine.for correctly microhardness testing. This process was repeated for each group. 16 samples for each group; 48 samples were prepared for a total of 3 groups. The microhardness of the top surfaces were measured using a Vickers hardness tester (Esetron,ODTU, Ankara). Microindentation was carried out using a 100 mN load with a 15 seconds dwell time.

| Material Name | Manufacturer | Material Type | Matrix Type | Filler Content | Filler Rate % |

|---|---|---|---|---|---|

| Surefil SDR Flow (SDR) | Dentsply Caulk, USA | Bulk Fill Flowable Composite | Dimethacrylate Resin EPDMA TEGDMA Modified UDMA BHT | Silicate Glass Silicate oxide Hybrid Fiber Glass | 80 |

| Filtek Bulk Flow (FBF) | 3M/ESPE St Paul, MN,USA | Bulk Fill Flowable Composite | UDMA Bis-GMA Bis-EMA Proacrilat resins TEGDMA | YBF3 Fillers Zirconia, silica particles | 64.5 |

| X-Tra Base Flow (XTB) | Voco Cuxhaven Germany | Bulk Fill Flowable Composite | Bis-GMA Bis-EMA UDMA Proxilat | Zirconia, silica particles, Ytterbium Trifluoride | 75 |

Table 1: Materials evaluated and respective manufacturer information.

Statistical analysis

The data were entered into statistical software package (IBM SPSS, V21). After the data were checked, one way ANOVA Variance Analysis were used to discuss microhardness of each material. Post Hoc Tukey Test was used for determination of the groups that make up differences. The significance level was set at p < 0.005.

Results

Microhardness values range from 22.79 to 33.1 for bulk fill flowable composites (Figure 2 and Table 2). According to the test of homogeneity of variances in the Table 3, significant value (0.120) was larger than 0.005 (Table 4), variance was homogeneous. For this reason we were used Post Hoc Tukey test for differences. Significant value (0.000) was found smaller than 0.005, and so the results of our study were positive and there were differences between the groups. Post Hoc Tukey Test was used for analyzing groups forms differ from others Table 5. Significant differences were found between groups. While the percentage of SDR is higher than 2.93 from FBF, lower than 6.16 from XTB. Meanwhile, the average of XTB was found higher than FBF (Table 5).

| 95% Confidence interval for Mean | ||||||||

|---|---|---|---|---|---|---|---|---|

| N | Mean | SW. Deviation | Std. Error | Lower Bound | Upper Bound | Minimum | Maximum | |

| SDR (Surefil SDR Flow) | 16 | 26.2356 | 0.6442 | 0.16105 | 258924 | 26.5789 | 25.03 | 27.11 |

| FBF (Utak Bulk Flow) | 16 | 232988 | 0.37288 | 0.9322 | 231001 | 23.4974 | 22.79 | 24.10 |

| <TB (X-tra Base Flow) | 16 | 324031 | 0.54733 | 0.13683 | 32.1115 | 32.6948 | 31.16 | 33.10 |

| Total | 48 | 273125 | 386956 | 0.55852 | 261889 | 284361 | 22.79 | 33.10 |

Table 2: Mean microhardness for all tested materials.

Discussion

Microhardness is defined as the blocking resistance that prevents the creation of permanent deformation and hardness is the most important feature contributes the success of clinical utilizations. A high microhardness value eventuates increasing the scratch and abrasion resistance, meanwhile prevents the material easily deformed against various forces [12-14].

According to a study conducted by Rouhollah et al., hardness is inversely proportional to the thickness of the composite. For this reason, the composite 2 mm thickness in each layer is proposed [14]. But in recent years due to developments in the bulk fill resin composites, the clinical fe atures high-composites are produced. We have detected in the our study, XTB is the most successful group.

| Microhardness | |||

|---|---|---|---|

| Levene Statistic | df1 | df2 | Sig. |

| 2.226 | 2 | 45 | 0.120 |

Table 3: Test of homogenity of variances.

| Sum of Squares | df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|

| Between Groups | 690.949 | 2 | 345.474 | 1.214.169 | 0.00 |

| Within Groups | 12.804 | 45 | 0.285 | ||

| Total | 703.753 | 47 |

Table 4: Significant value.

| Multiple Comparisons Dependent Variable: Microhardness Tukev HSD | ||||||

|---|---|---|---|---|---|---|

| (I) Composites | (J) Composites | Mean Difference (4) | Std. Error | Sig. | 95% CAInfidtnCe Late | |

| Lower Bound | Upper Bound | |||||

| SDR (Surefil SDR Flow) | FBF (Hick Bulk Flow) | 2.93688* | 0.18859 | 0.000 | 24.798 | 33.939 |

| XTB (X-tta Base flow) | -6.16750* | 0.18859 | 0.000 | -66.246 | -57.104 | |

| FBF (FatekBulklow) | SDR (Surefil SDR Flow) | -2.93688* | 0.18859 | 0.000 | -33.939 | -24.798 |

| XTB (X-tta Base flow) | -9.10438* | 0.18859 | 0.000 | -95.614 | -86.473 | |

| XTB (X-1ra Base Flow) | SDR (Surefil SDR Flow) | 6.16750* | 0.18859 | 0.000 | 57.104 | 66.246 |

| FBF (Filtek Bulk Flow) | 9.10438* | 0.18859 | 0.000 | 86.473 | 95.614 | |

Table 5: Post hoc tukey test results for analyzing differences between groups.

Studies demonstrate that FBF’s microhardness value after 24 h Post-cure dry storage at 37°C was found as 24.0 and in our study we calculates this values as 23.29. So, It was similar that

Alshal et al. [15] in vestigated FBF’s microhardness value after 24 h Post-cure dry storage at 37°C. Six bulk fill composites were used in that study. Researchers found the hardness for FBF as 24.0. However, in this study, FBF displayed similar results.

Kim et al. [8] researched the effect of resin thickness on the microhardness and optical properties of bulk-fill resin composites. They have used four differenet bulk fill composites in their study. They found microhardness of SDR at 4 mm thickness as 29.48. In our study we found this value as 26.23. Differences in the equipment used, the molds used during the preparation of the samples and the homogenous placement of the material into the molds could be effective in obtaining different results in different studies. Differences in the equipment used, the molds used during the preparation of the samples and the homogenous placement of the material into the molds could be effective in obtaining different results in different studies.

Biasi et al. [16] demonstrated microhardness and its daily clinical. This was also confirmed by Ilie et al. [17] where SDR showed the lowest surface hardness from others. However, when compared to the investigated flowable of our study, SDR flow showed higher microhardness.

Simon et al. [18] determined the Influence of increment thickness on microhardness and dentin bond strength of bulk fill resin composites. the conventional resin composite Filtek Supreme XTE (XTE) and the bulk fill resin composites SDR (SDR), Filtek Bulk Fill (FBF), xtra fil (XFIL), and Tetric EvoCeram Bulk Fill (TEBF) after 24 h storage were analyzed. Microhardness was measured at different depths. SDR showed microhardness medians of 35.5 at 4mm. In this study, this values was found as 26.23 at 4 mm thicness.

Conclusion

All tested materials showed differences. Assesment of surface hardness ratio is that, XTB were found having the highest hardness and FBF had minimum hardness value. Accordingly, the results of the current study indicate, it may be preferable in clinical cases XTB, SDR and XTB respectively.

References

- Jackson RD, Morgan M (2000) The new posterior resins and a simplified placement technique. J Am Dent Assoc 131: 375-383.

- Bayne SC, Thompson JY, Swift EJ Jr, Stamatiades P, Wilkerson M (1998) A characterization of first-generation flowable composites. J Am Dent Assoc 129: 567-577.

- Summit JB, Hilton TJ, Schwartz RS (2006)Fundamentalis of Operative Dentistry A Contemporary Approach pp: 289-339.

- Ikeda I, Otsuki M, Sadr A, Nomura T, Kishikawa R, et al. (2009) Effect of filler content of flowable composites on resin-cavity interface. Dent Mater J 28: 679-685.

- Watts DC, Amer OM, Combe EC (1987) Surface hardness development in light-cured composites. Dent Mater 3: 265-269.

- Ilie N, Bucuta S, Draenert M (2013) Bulk-fill resin-based composites: an in vitro assessment of their mechanical performance. Oper Dent 38: 618-625.

- Say EC, Civelek A, Nobecourt A, Ersoy M, Guleryuz C (2003) Wear and microhardness of different resin composite materials. Oper Dent 28: 628-634.

- Kim EH, Jung KH, Son SA, Hur B, Kwon YH, et al. (2015) Effect of resin thickness on the microhardness and optical properties of bulk-fill resin composites. Restor Dent Endod 40: 128-135.

- Lassila LV, Nagas E, Vallittu PK, Garoushi S (2012) Translucency of flowable bulk-filling composites of various thicknesses. Chin J Dent Res 15: 31-35.

- (2009) Surefil®SDRTM flow Posterior Bulk Fill Flowable Base, Directions for usedentsply.

- Czasch P, Ilie N (2013)In vitro comparison of mechanical properties and degree of cure of bulk fill composites. Clin Oral Investig 17: 227-235.

- Jendresen MD (1993) Clinical behavior of 21st-century adhesives and composites. Quintessence Int 24: 659-662.

- Manhart J, Kunzelmann KH, Chen HY, Hickel R (2000) Mechanical properties of new composite restorative materials. J Biomed Mater Res 53: 353-361.

- Rouhollahi M, Mohammadibasir M, TalimSh (2012) Comparative depth of cure among two light-cured core build-up composites by surface vickers hardness. J Dent (Tehran) 9: 255-261.

- Alshali RZ, Salim NA, Satterthwaite JD, Silikas N (2015) Post-irradiation hardness development, chemical softening, and thermal stability of bulk-fill and conventional resin-composites. J Dent 43: 209-218.

- De Biasi M, Calvi R, Sossi D, Maglione M,Angerame D (2010) Microhardness of a new flowable composite liner for posterior restorations. Dental Materials26: e25.

- Ilie N,Hickel R (2011) Investigations on a methacrylate-based flowable composite based on the SDR technology. Dent Mater 27: 348-355.

- Flury S, Peutzfeldt A, Lussi A (2014) Influence of increment thickness on microhardness and dentin bond strength of bulk fill resin composites. Dent Mater 30: 1104-1112.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences